Concrete is a commonly used building material that makes planters durable and strong.

For example, in the public landscape areas of specific cities, huge concrete planters are frequently placed. These are filled to the brim with a wealth of flowers and lush plants, serving as adornments and providing space for the flourishing of plants. In some private gardens, people also choose concrete planters to create distinctive garden scenes. You should explore four aspects of concrete planters: materials, plant adaptability, the manufacturing process, and where to find a reliable supplier.

What are the differences between cement and concrete?

Are concrete planters good for plant?

How to make concrete planters lightweight and durable?

How do manufacturer make lightweight concrete planter?

What does a reliable manufacturer of concrete planters look like?

1. What are the differences between cement and concrete?

"Cement is a highly refined fine powder that plays a vital role as a binder when mixed with water, sand, and gravel. Once these elements are combined, they give rise to a substance known as concrete. Concrete, conversely, is a complex and highly engineered composite material that consists of cement, aggregates (such as fine sand, coarse gravel, or crushed stone of varying sizes), water, and in some cases, additional additives that are specifically included to enhance its properties.

The main differences between cement and concrete can be clearly identified as follows:

- Composition

-Cement constitutes merely a single component within the overall composition of concrete. Concrete is a meticulously balanced blend of multiple components, each contributing to its unique characteristics and performance.

- Physical state

-Cement exists in the form of a fine powder. In contrast, concrete emerges as a solid and substantial mass, having undergone a chemical and physical transformation during the mixing and curing process.

- Use

-Cement, when considered alone, lacks the necessary structural integrity and mechanical properties to be directly used in construction projects. Concrete, on the other hand, is widely employed in a broad range of building and construction projects, ranging from the laying of large-scale structures' foundations to the creation of intricate architectural elements.

- Strength and properties

-Concrete exhibits superior strength and load-bearing capacity as a result of the strategic combination and interaction of its constituent materials. This synergy enables it to withstand significant compressive and tensile forces, making it an indispensable material in modern construction.

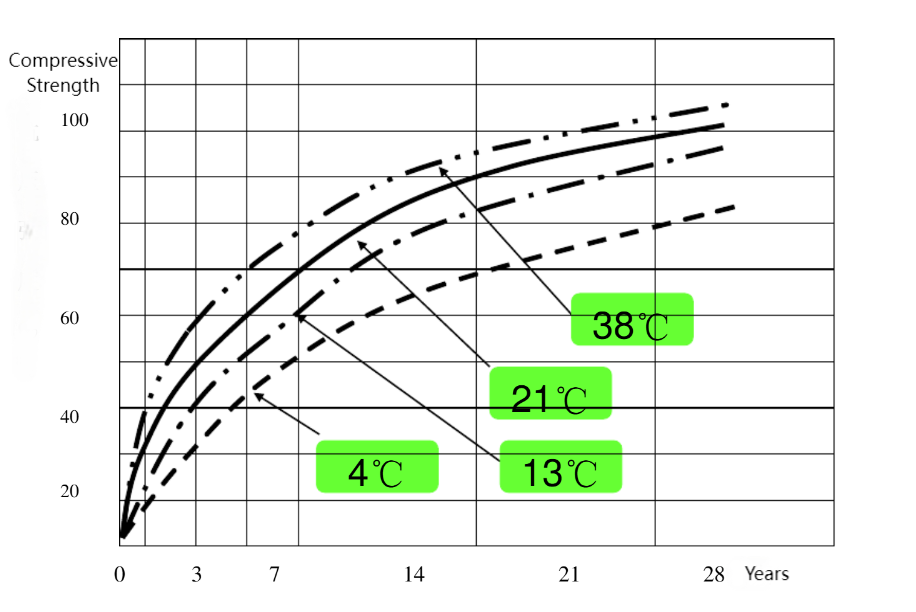

Graph of the change in compressive strength of concrete over time at different temperatures.

The compressive strength refers to the ability of a material to resist destruction under pressure.

It is usually used to describe solid materials such as metals, rocks, and concrete, and how much pressure they can withstand before breaking, deforming, or failing.

For example, in the field of architecture, the compressive strength of concrete is an important indicator for evaluating its quality and suitability. Suppose that the design compressive strength of a certain type of concrete is 30 MPa. If the pressure it is subjected to in actual use exceeds 30 MPa, the concrete structure may develop cracks and even collapse.

The determination of compressive strength is usually carried out through specialized experimental equipment and methods, and the resulting data is used for material selection, engineering design, and quality control.

To sum up, cement serves as an essential ingredient in the formulation of concrete. Nevertheless, they have notably distinct characteristics and application scenarios, each fulfilling specific requirements within the domain of construction and engineering."

2. Are concrete planters good for plant?

Concrete planters can truly prove beneficial for plants in specific circumstances; however, it's essential to be conscious that they might also have some potential disadvantages.

The favorable aspects of concrete planters are quite remarkable. Their durability is a significant factor as they are designed to withstand the challenges of outdoor environments. They remain steadfast and stable, being less likely to tip over even when confronted with strong winds or other external forces. The damage they are prone to is minimal. Furthermore, concrete has the capacity to retain heat effectively. This characteristic proves advantageous for certain plant types that thrive in warmer root zones, especially in regions with cooler climates. Such plants can enjoy a more favorable growth environment thanks to the heat retention provided by the concrete planters.

On the contrary, concrete has a porous nature, and this can give rise to problems. Water seepage occurs more readily through these pores, resulting in moisture loss at a faster rate compared to non-porous materials. As a consequence, this demands more frequent watering to maintain the sufficient moisture levels necessary for the plants' survival and growth. Additionally, in cases where the concrete is not properly sealed or treated, there is a possibility that substances could leach out over time. These substances might potentially have adverse effects on the plants' health and well-being.

More or less, concrete planters can turn out to be a suitable choice for a wide range of plants. Nevertheless, it is of the utmost importance to take into account the specific requirements and needs of the plants one desires to cultivate. Appropriate measures should then be adopted to effectively manage and mitigate the potential issues that might arise.

As a manufacturing factory of concrete material and GRC material, Ronglin has numerous products that have been in use for over ten years. Moreover, these products are also part of our company's decoration. We would be more than happy to invite like-minded individuals to visit our company.

3. How to make concrete planters lightweight and durable?

To make concrete planters lightweight and durable, you can follow these steps:

1. Utilize lightweight aggregates like expanded clay, perlite, or vermiculite in the concrete mixture to reduce weight while maintaining durability.

2. Incorporate fibers such as fiberglass or polypropylene fibers to enhance the strength and durability of the concrete, allowing for a thinner and lighter structure.

3. Optimize the concrete mix by carefully proportioning the cement, sand, and water to improve quality and durability while minimizing weight.

4. Consider creating hollow sections within the planter to reduce the amount of concrete used, making it lighter without sacrificing much durability.

5. Apply a high-quality sealer or coating to protect the concrete from damage and increase its durability over time.

While making a concrete planter, it is also important to keep the following points in mind:

Adding lightweight aggregate while mixing the materials

-By adding lightweight materials such as expanded clay, perlite, or vermiculite to the concrete mixture, you can reduce the overall weight while maintaining durability. Lightweight aggregates need to be specially formulated, and without proper experience, they may cause varying degrees of problems in the mixed material.

Adding fibers

- Adding fibers such as glass fiber or polypropylene fiber can enhance the strength and durability of concrete, making the structure of the planter thinner and lighter. Ronglin often uses specialized tools for spraying when making concrete planters, spraying the mixed material and covering it with a layer of glass fiber, then continuing to spray the mixed material.

Optimizing concrete mix ratio

- Carefully adjust the proportions of cement, sand, and water in the concrete mix to improve the quality and durability of the concrete while minimizing its weight. Different material ratios can often affect the final product's appearance, so Ronglin sends the mixture of materials used in their concrete planters to a laboratory for testing before pairing them to ensure that the proportions are correct.

Apply protective coating

- Applying a high-quality sealant or coating can protect concrete from damage and improve its durability over time. Protective coatings on the market are usually made with chemicals, and if used improperly, they can cause uncontrollable damage to plants and even harm users. Ronglin's concrete planters are made with natural mineral materials and sandstone without any chemical coating.

It is worth noting that achieving both lightweight and durability at the same time often requires experimentation and finding the appropriate combination of methods based on specific requirements and conditions.

If you want to make a high-quality concrete planter that is both lightweight and durable, professional production tools are essential. As a factory that has been producing lightweight concrete planters for 20 years, you can refer to our related production videos for different inspirations when making concrete planters.

5. What does a reliable manufacturer of concrete planters look like?

A short delivery period

When considering the entire concrete planter production industry in its entirety, due to the labor costs and environmental protection issues involved in the manufacturing process, a long production cycle is a disadvantage of cement planters. This is also the reason why cement planters produced locally in many developed countries have such exorbitant prices. Ronglin has established its production bases and companies in different cities, which not only takes local employment issues into account but also protects the environmental protection of the cities simultaneously, addressing the problem of long delivery periods from the source.

A wide variety of highly customizable and competitive products

Ronglin boasts professional designers for product appearance and structure, offering comprehensive customization services ranging from materials, molds, processes, to packaging, in order to create unique concrete planters that truly stand out. Our team frequently achieves unexpected results when delving deeply into discussions on the market adaptability of new products, much like our best-selling products on major e-commerce sales platforms. We are constantly endeavoring to make new breakthroughs and lead the gardening industry.

In conclusion

Concrete planters are a frequently chosen option in gardening. They are durable and robust, fabricated from a material capable of retaining heat. Nevertheless, they possess porous characteristics that might lead to water seepage and necessitate more frequent watering. To render them lightweight and durable, approaches such as the utilization of lightweight aggregates, the addition of fibers, the optimization of the mixture, the consideration of hollow designs, and the application of a protective coating can be adopted.

A reliable manufacturer of concrete planters, like Ronglin, boasts professional designers, provides comprehensive customization services, and guarantees a short delivery period. They create distinctive and competitive products and constantly strive for innovation within the gardening industry. Cement is a component of concrete, and they have distinct features and uses. Overall, concrete planters can be a favorable choice depending on the requirements of the plants and the proper management of potential issues.